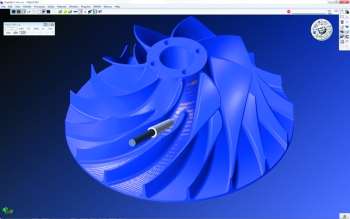

New Turbo Machinery Options Offer Economical, Specialized Solutions to Machining Bladed Parts

Gibbs and Associates has announced that two new GibbsCAM options specialized for simplifying the machining of turbo machinery parts (rotary parts with blades) will be previewed at EMO, the annual international trade fair for metalworking technology.

The two new GibbsCAM options, 5-Axis-MultiBlade and 5-Axis-Advanced MultiBlade, are fully integrated into GibbsCAM for use on machining centers and MTM machines. The options offer two levels of sophistication, both built with a specialized and dedicated interface within the GibbsCAM 5-Axis option. The MultiBlade interface provides access to toolpath strategies used in machining bladed parts, such as impellers, blisks (bladed disks) and blings (bladed rings), which are used in multiple industries where fluid (gas or liquid) compression or pressurized flow is required, chiefly aerospace, automotive and power generation.

“The desire for efficiency is driving rapid growth of 5-axis machine tool use and the trend toward making turbo machinery parts is expanding beyond familiar components such as those within jet engines. Both trends provide a great opportunity for manufacturers to adopt our 5-Axis-MultiBlade Options” said Robb Weinstein, Senior Vice President of Sales and Strategic Planning of Gibbs and Associates.

While the GibbsCAM 5-Axis module is a powerful multi-purpose programming tool, very capable of generating toolpath for all parts requiring simultaneous 5-axis motion, the MultiBlade Options simplify machining of bladed parts, beginning with its integration within the GibbsCAM environment. Equally important is an intuitive, easy-to-use interface, which uses common turbo machinery terminology. Another simplification is that geometric manipulation is not necessary, because the MultiBlade Options work directly from the geometric model. Users need only select predetermined items such as the hub, blade, shroud, etc., to begin programming. Furthermore, toolpath strategies available within MultiBlade are only those required or typically used to machine those geometric elements, but with all the flexibility to specify machining parameters.

The GibbsCAM 5-Axis-MultiBlade Option is designed for machining parts of simple to moderate complexity, and provides a subset of the features within the 5-Axis-Advanced MultiBlade Option, which adds functionality for machining highly complex parts. User requirements determine which module is best for the individual manufacturer.

Want more information? Click below.